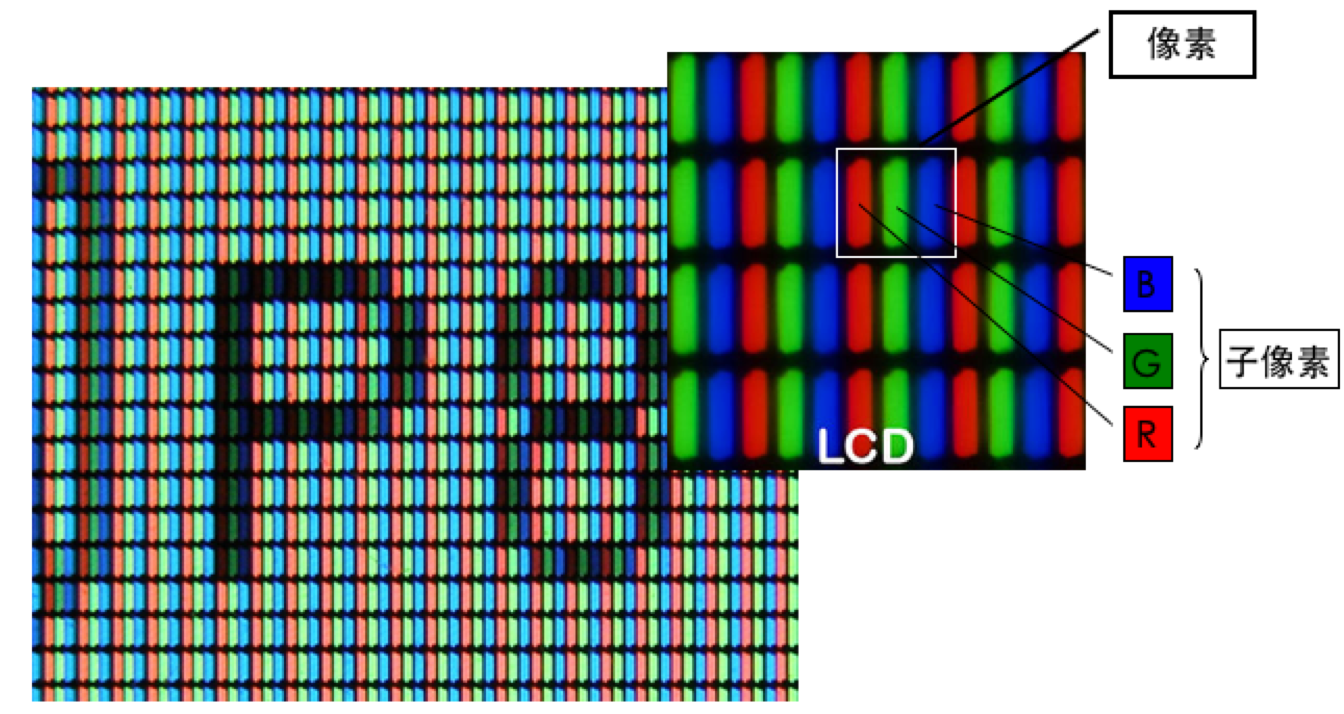

TFT technology,it is short for Thin-Film-Transistor technology. It is the mainstream technology for color display in flat display industry.

To achieve color display, TFT technology divides one pixel into 3 color sub-pixels, which is called "RGB" pixel. By driving differently to these sub-pixels, it can perform different color by different mixing ratio of each RGB pixel.

Techshine Electronics focus on small and middle size TFT module production, who can support from 0.96 to 7.0 inch in-house TFT module process, including Touch Panel assembly and full-lamination.

The process line up for TFT module and TP lamination:

2 full-automatic lines of TFT small size module process

2 high speed full-automatic lines of TFT middle size module process

1 semi-automatic line of TFT module process (up to 15.6 inch)

Total capacity for TFT module is 52Kpcs per day.

1automatic&1semiautomatic optical bonding lines based on OCA technology

Optical bonding capacity is 10Kpcs per day.

Techshine's TFT module product is widely applied on---POS, IP Phone, Home Appliance, White goods, Industrial HMI, Healthcare devices, etc

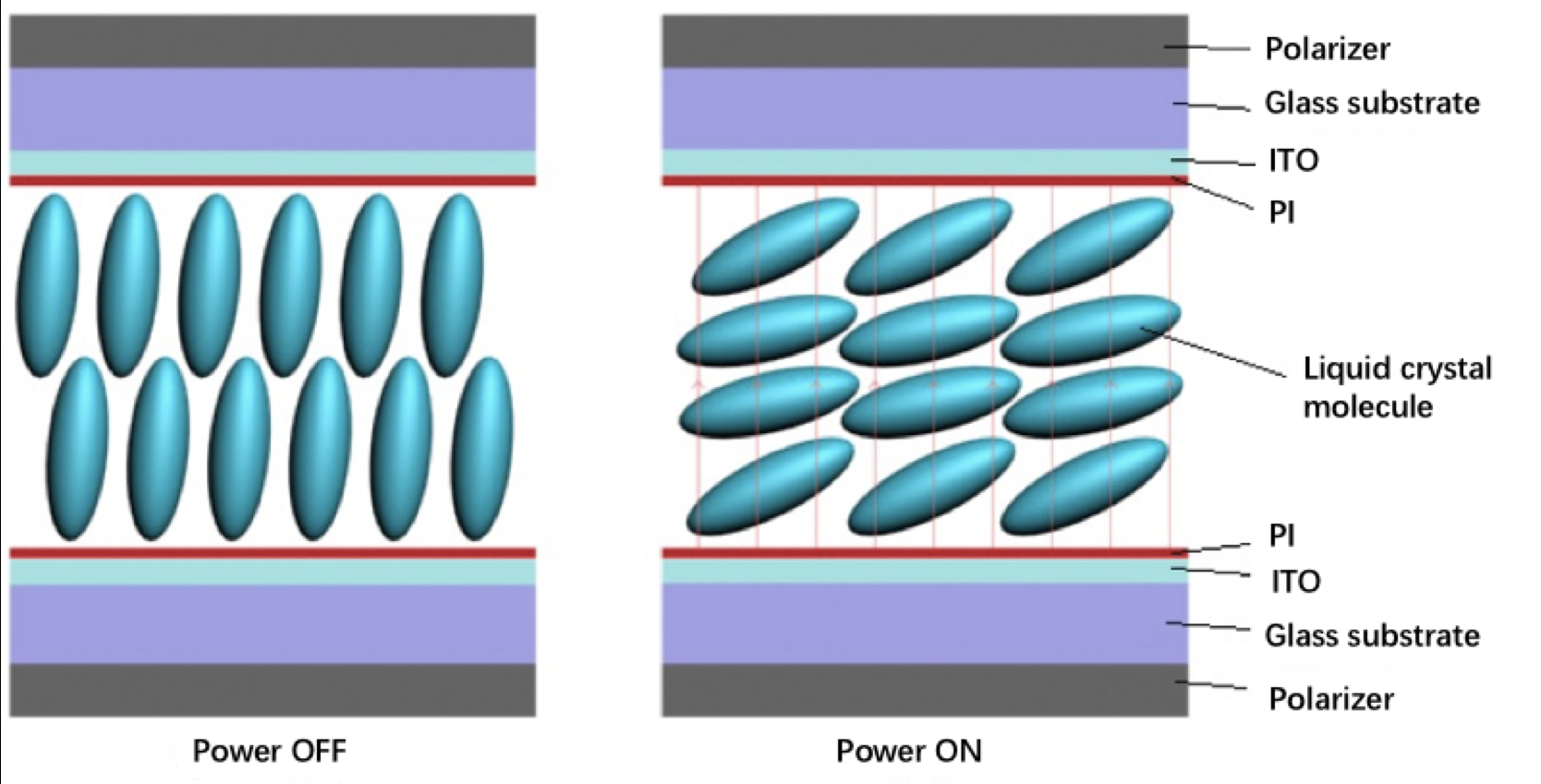

VA technology,it is short for Vertical Alignment technology. Different from TN/STN technology, the liquid crystal molecule is standing vertically when power off. By which, VA LCD can achieve pure black background color and super high contrast ratio of 500:1 to 2000:1.

Cross-section View of VA LCD Panel:

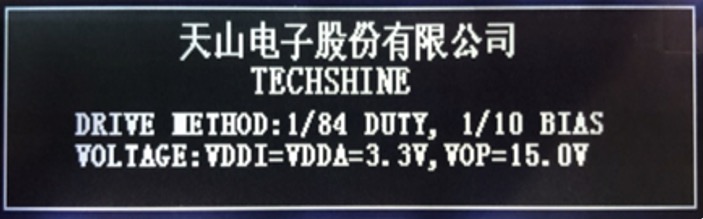

Techshine Electronics has successfully developed both Segment Type and Graphic Type VA product.

Techshine Electronics has set up 2 high-grade STN front process line. Both of the lines are running 14*16 inch mother glass. The mass production started at 2011(1st STN line) and 2016(2nd STN line). By which Techshine can support full-customized VA LCD solution and production, whit high contrast ratio and wide view angle. By year of 2017, Techshine also achieve mass production of middle-big size VA LCD(From 4~12 inch) , and graphic type VA LCD with 1/64duty.

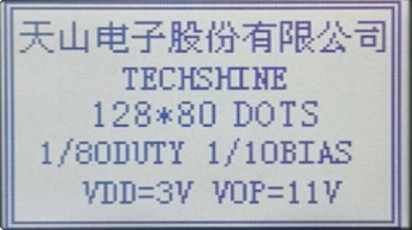

STN technology,it is short for Super Twisted Nematic technology. Normally, the liquid crystal molecule is twisted at 240 degrees, which has a bigger twisted angle comparing to TN technology.

Comparing STN to TN, the viewing angle of STN is wider than TN under the same driving condition.

The main advantage of STN technology is it can support high resolution graphic display up to 320*240 dots.

Techshine Electronics has set up 2 high-grade STN front process line. Both of the lines are running 14*16 inch mother glass. The mass production started at 2011(1st STN line) and 2016(2nd STN line). Daily capacity is 5,500 sheets (Around 500Kpcs of 2.0inch LCD size).

Main Structure of STN LCD:

STN LCD PANEL,by Zebra or Heat-seal connection to customer board

STN LCD PANEL+Metal PIN, by socket or soldering connection to customer board

STN LCD PANEL+FPC/HSC, by ZIF/B2B connector or soldering connection to customer board

STN LCD PANEL+COG+FPC/Metel PIN, by ZIF/B2B connector or soldering connection to customer board

STN LCD COB Module

TN technology,it is short for Twisted Nematic technology. Normally, the liquid crystal molecule is twisted at 90 degrees. Comparing to other LCD panel technologies, TN type has the merit of lower cost and quick response time, which is mostly used for customized segment pattern display.

Main structure of TN LCD solution:

TN LCD PANEL,by Zebra or Heat-seal connection to customer board

TN LCD PANEL+Metal PIN, by socket or soldering connection to customer board

TN LCD PANEL+FPC/HSC, by ZIF/B2B connector or soldering connection to customer board

TN LCD PANEL+COG+FPC/Metal PIN, by ZIF/B2B connector or soldering connection to customer board

Cross-section view of TN LCD panel: